The scanning of barcodes forms a very important component of contemporary companies. In retail and logistics, healthcare and manufacturing, barcode scanning is done accurately to carry out smooth operations. Even the slightest scanning faults, nevertheless, may lead to a mismatch in stock, late deliveries, billing issues, and customer dissatisfaction. This guide will discuss the most frequent pitfalls in barcode scanning and how they can be addressed and prevented. The use of the most appropriate barcode labels in India will also be targeted to reduce errors and enhance efficiency.

Understanding Barcode Scanning Errors

The barcode scanning errors are those that are experienced when scanners do not read barcodes in a consistent manner. These mistakes are frequently occasioned by:

- Low-quality labels

- Wrong material choice

- Barcodes that are faded or not well printed.

- Heat, moisture, or chemical environmental factors.

India Scanning errors can be significantly minimized by using custom barcode labels that are used based on your requirements. Adequately developed labels, keeping in mind their size, material, and position, expedite the scanning process and enhance its accuracy.

Why Does Barcode Label Quality Matter?

Barcode labels serve as the intermediary between the physical products and the digital systems. In case this bridge is frail, the flow of work is impaired. Indian barcode labels are the best, as they make sure that:

- Rapid and more precise scanning.

- Reduced manual data entry

- Lower operational costs

- Better inventory control.

The cheap labels can appear to be economical; however, they end up giving more losses since they tend to fail in scanning.

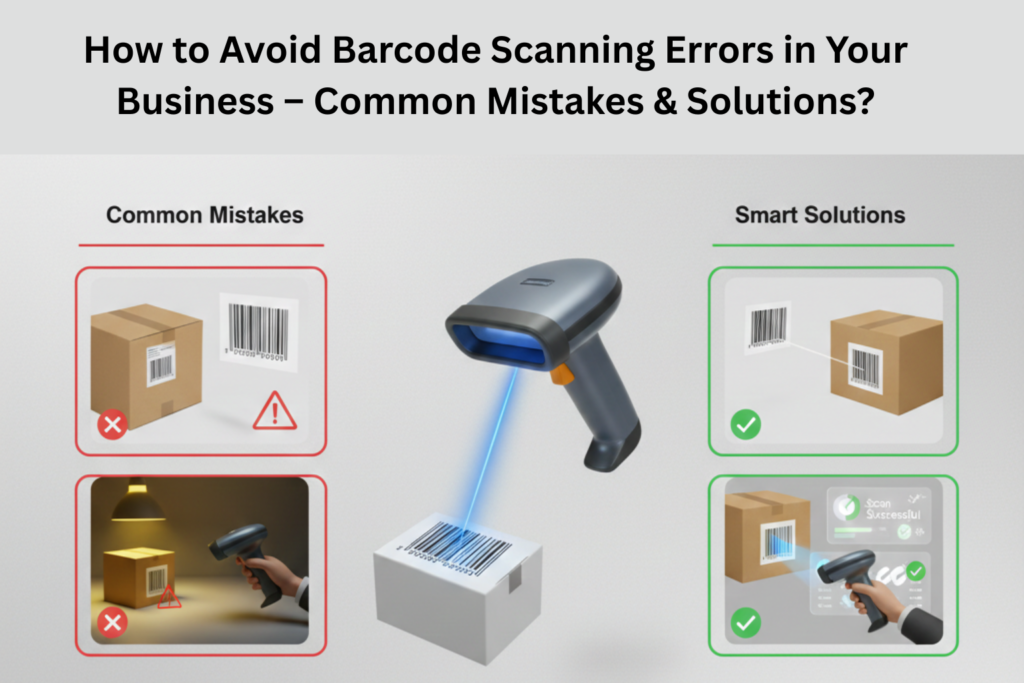

Common Barcode Scanning Mistakes Businesses Make

Low-Quality Barcode Labels.

The use of cheap labels containing low-grade adhesive or paper is one of the most common mistakes. Barcodes may be destroyed as a result of these labels that tear, fade or peel. The selection of the optimal paper barcode labels in India or synthetic barcode labels in India greatly enhances the problem of scanning.

Mistaken Decision on Paper and Synthetic Barcode Labels.

Numerous businesses make use of paper labels when synthetic labels should be applied. This leads to errors:

- Paper barcode labeling in India is suitable in dry indoor conditions where there is less handling.

- In India, synthetic barcode labels are superior to heat, moisture, chemicals and outdoor.

Choosing the incorrect material may lead to smudging, fading and constant breakdowns of the scanner.

The barcode labels have poor print quality.

Scanners should be very contrasted in the bars and their background. Poor scanning accuracy of faded prints, low-quality printing, or bad ink quality. Investing in good-quality printers and tailor-made barcode labelling in India will guarantee good prints, which will be read immediately by the scanners.

Negligence of Environmental Conditions.

Barcode labels can be destroyed by environmental conditions like heat, moisture, dust, and handling stress. The use of synthetic barcode labels in India will increase lifespan in harsh environments such as warehouses, cold storage, or industrial environments.

Lack of Security Measures

In industries like pharmaceuticals, FMCG, and logistics, barcode tampering can cause serious losses. The best tamper-evident barcode labels in India provide security by showing visible evidence if removed or altered. This prevents:

- Fraud

- Product duplication

- Supply chain manipulation

Solutions to Avoid Barcode Scanning Errors

It is necessary to select optimal barcode labels in India that would ensure smooth operations. Quality labels are provided with good stickers to ensure long durability, durable material to endure tough environments and high-resolution printing to ensure precise scanning. Premium labels minimize mistakes, enhance performance, and give solid inventory control. Businesses can be professional, streamline their businesses and improve overall productivity with the right barcode labels.

Select the Right Material – Paper vs Synthetic

Choosing the correct material is key:

- Paper barcode labels in India: Ideal for retail, cartons, and indoor storage.

- Synthetic barcode labels in India: Suitable for outdoor use, transport, and industrial environments.

Proper material selection prevents fading, smudging, and scanner rejection.

Use Custom Barcode Labels for Accuracy

classifications are inapplicable to all situations. The custom Printer barcode labels in India permit companies to identify:

- Label size and shape

- Adhesive type

- Finish (glossy or matte)

- Branding and compliance printing.

Customization also makes the barcodes scan properly and reliably.

Upgrade to Tamper-Evident Barcode Labels

Tamper-evident labels are crucial for high-value or sensitive products. They prevent unauthorized removal and ensure product authenticity, which is essential for industries like pharma, FMCG, and logistics.

Industry-Wise Barcode Label Solutions

Retail & FMCG

In India, retailers need paper barcode labels that have readable and clear barcodes that perform well on packaging and shelves.

Logistics & Warehousing

Synthetic barcode labels are used to the advantage of warehouses and logistics firms in India, subject to the handling, the moisture, and the transit environment.

Manufacturing & Healthcare

In India, manufacturers and hospitals use custom barcode labels and tamper-evident barcode labels for traceability, compliance, and safety.

Best Practices for Barcode Printing & Scanning

To reduce scanning errors, the following should be practiced by the businesses:

- Keep the best printer resolution.

- Make sure that the barcodes are of the appropriate size and have silent areas.

- Label clean and flat surfaces.

- Clean scanners regularly

- Alteration of test barcode readability before bulk application.

All these best practices, coupled with quality labels, will guarantee efficiency in the long term.

Choosing the Right Barcode Label Partner

A reliable label manufacturer understands material selection, print quality, and industry standards. Working with a trusted partner provides:

- Consistent quality

- Faster turnaround

- Custom solutions

- Long-term outcomes are cost-effective.

Conclusion

Barcode scanning errors are not incidental in the Brahi form but rather due to bad label selection, use of wrong materials, and failure to customize. By investing in the most superior barcode labels in India, making the right choice between paper and synthetic barcode labels, and using custom and tamper-evident barcode labels, businesses can permanently avoid scanning problems.

A properly constructed barcode system with correct branding will result in ease of business, greater precision, and increased customer confidence; hence, it is a smart choice for every expanding company in India.